After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

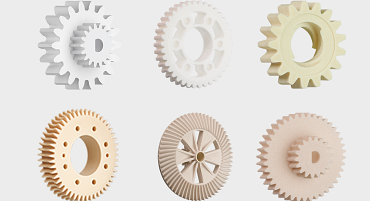

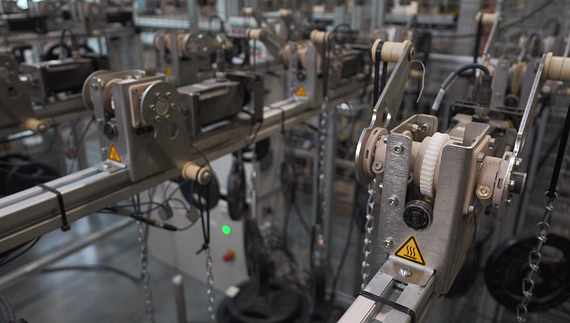

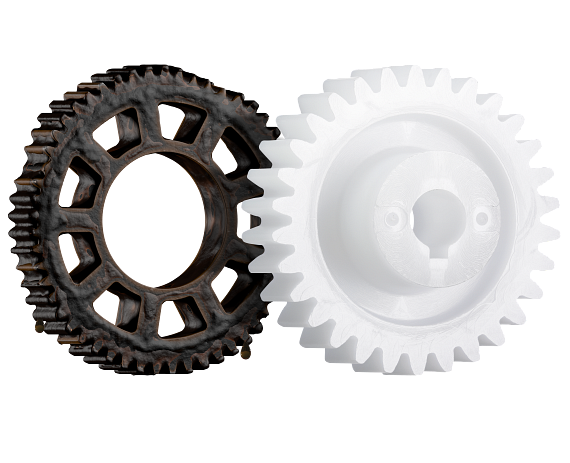

Cost-Effective: igus® gears are often more affordable than metal gears, providing a cost-effective solution without compromising on performance.

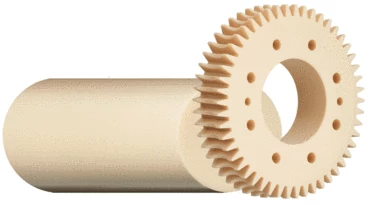

Customizable: igus® offers a wide range of gear designs and sizes, and they can be customized to meet specific application requirements, ensuring optimal performance for any project.

Quiet Operation: The plastic material helps to dampen noise, resulting in quieter operation compared to metal gears, which is beneficial in noise-sensitive environments.

Maintenance-Free: These gears are self-lubricating, which means they do not require regular maintenance or lubrication, reducing downtime and maintenance costs.

Corrosion-Resistant: Unlike metal gears, igus® gears are resistant to corrosion, making them ideal for use in environments where moisture or chemicals are present.

Lightweight: The plastic construction of igus® gears makes them significantly lighter than their metal counterparts, which can help reduce the overall weight of machinery and improve energy efficiency.

Monday to Friday from 8:30 am - 5:30 pm.

24h