After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

Flexibility even with small batches and the automation of processes is one of the biggest challenges, not only in the packaging and beverage industry. However, outdated production facilities and high set-up costs often stand in the way of these goals.

Automated format adjustment is one way out. By converting large parts of a production plant with just one simple step, operating time is optimised, higher throughput is achieved and setup costs are minimised.

Automated format adjustment is increasingly being used in modern packaging machines and production lines. However, major cost savings can also be achieved by retrofitting automated format adjustment in existing production plants. The modular gearbox system makes it easy and space-saving to integrate lane adjustments, curve adjustments and lateral guides of conveyor systems into existing systems. Most of the simple assembly can be carried out while production is ongoing, so that downtime is minimised.

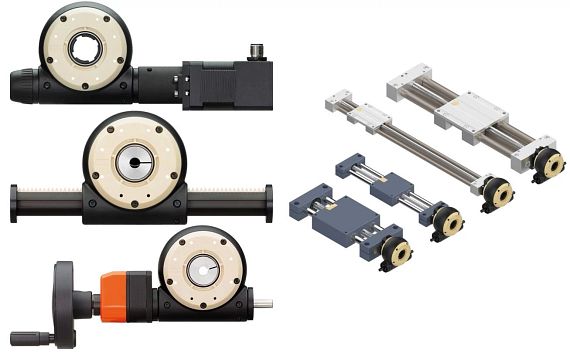

With the drygear® Apiro® modular gearbox, igus® offers a modular system for any type of automation that can be used to build a wide variety of kinematics in a modular and flexible way.

The drygear® Apiro® modular system offers different transmissions and lengths, so that there are endless possibilities for combinations and applications. In addition to lane adjustments, curve adjustments, pusher applications, rotary tables or even Cartesian robots can be set up.

_135x135.png)

Monday to Friday from 8:30 am - 5:30 pm.

24h